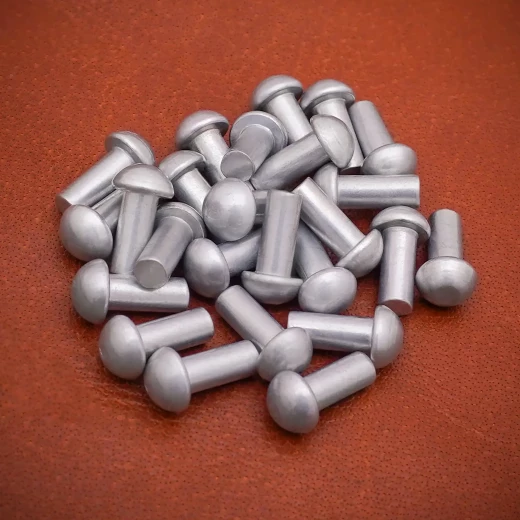

Round Head Rivets, 16x4 mm, Mild Steel, Pack of 25

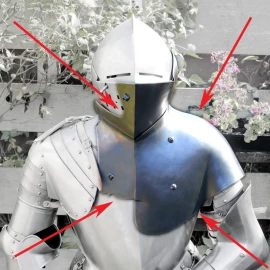

It's the details that separate a masterpiece from the average. With these mild steel round head rivets, you get the fundamental building block for your historical projects. Whether you are making or repairing plate armour, assembling a helmet, attaching leather straps, or building a sturdy shield, these rivets will provide you with a strong and period-accurate join. They are made from mild steel, which is strong enough to withstand stress while also being malleable enough to form well when peened. Their classic dome head is typical for armour from the 12th to the 16th century. This practical pack contains 25 pieces, ready for your workshop. Further product information ...

Round Head Rivets, 16x4 mm, Mild Steel, Pack of 25

The Unsung Heroes of History

Rivets are truly the unsung heroes of craftsmanship. Without them, the complex constructions of plate armour that protected knights in battle would never have been possible. The round head was not just an aesthetic choice—its smooth, domed shape helped to deflect weapon blows and prevented snagging on clothing or equipment. You can find these rivets on hundreds of museum exhibits, from brigandines to cuirasses, gauntlets, and gorgets. With this set, you can work with a material that is close in properties and appearance to what the armourers of old used.

How to Properly Set a Rivet (Peening)

Creating a strong riveted joint is a fundamental skill for any armourer or leatherworker. It's not complicated:

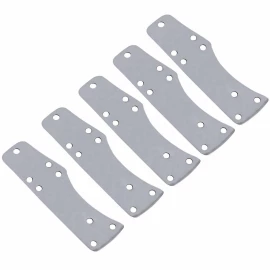

- Prepare the materials you want to join (e.g., two steel plates) and drill or punch a 4 mm hole through them.

- Insert the rivet through the hole. Place the dome head of the rivet on a solid surface, ideally in a rivet set (a steel block with a depression) to prevent it from deforming during work.

- The rivet shank should protrude on the other side by about 1.5 times its diameter (in this case, about 6 mm). If it's longer, trim it with a hacksaw.

- Using the ball end of a ball-peen hammer (or a specialised riveting hammer), begin to gently tap the end of the shank to mushroom it out. Use circular motions, working from the centre to the edges.

- Gradually form the second head, the "shop head," which should also have a dome shape. The goal is for the rivet to securely clamp the joined materials together without any play.

Tip: For a better result, the end of the shank can be heated to a red glow before peening; the steel will be more pliable.

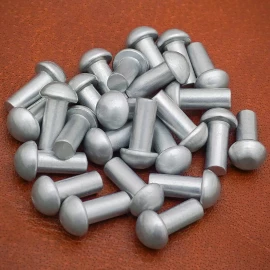

Technical Specifications

| Overall Length: | 16 mm |

| Shank Length: | 12 mm |

| Shank Diameter: | 4 mm |

| Head Diameter: | 6.2 mm |

| Head Type: | Round / Dome Head |

| Material: | Mild Steel |

| Package Contents: | 25 pieces |

Care of Steel Components

Remember that this is an unalloyed steel that is not resistant to corrosion. Proper storage is important to maintain their quality.

Rust Prevention is Key

Store the rivets in a dry environment, ideally in a closed box. Once installed on the final product, they will be protected by the surface finish of the entire piece (oiling, waxing, painting). If you want the rivets to maintain their shine, you can lightly coat them with oil. For many historical projects, however, a light, natural patina is actually desirable.

We are here for you!