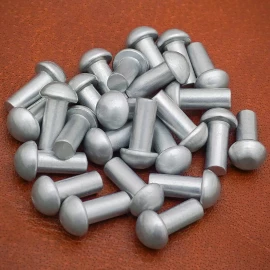

Round Head Brass Rivets 4x13 mm, Pack of 25

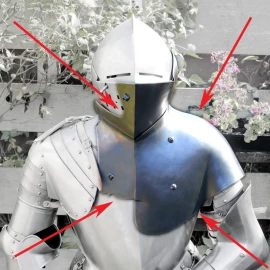

Honest craftsmanship requires honest materials. This pack of 25 solid rivets made from solid brass is exactly what you need for your historical projects. Thanks to their classic round head and robust construction, they are ideal for creating strong, period-accurate joints on leather, metal plates, or for attaching fittings and buckles. Being made of brass, you don't have to worry about corrosion. This makes them a perfect choice for making and repairing armour, bags, and other gear for LARP, reenactment, or the SCA world. The longer 13 mm shank makes them ideal for joining thicker layers of material. Further product information ...

Round Head Brass Rivets 4x13 mm, Pack of 25

Essential Fasteners for Your Projects

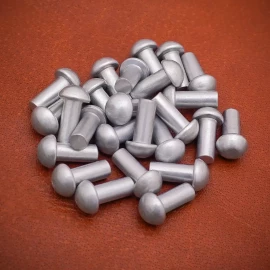

These solid rivets are designed for the traditional method of riveting by peening. Unlike modern pop rivets, they create an extremely strong and durable joint that is also historically accurate. The 13 mm shank length is sufficient for joining several layers of thick leather or for attaching accessories through thicker material.

How to Set Rivets Correctly

Riveting is a skill you can easily master. The process is as follows:

- Drill or punch a hole in the materials to be joined with a diameter matching the rivet shank (in this case, approx. 4 mm or 5/32 in).

- Push the rivet through the hole. Rest the rivet head on a solid surface, ideally with a small depression (a rivet set) to avoid damaging its round shape.

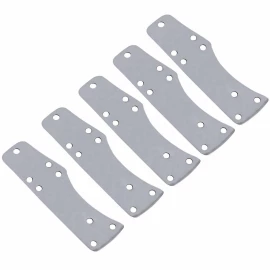

- For best results, especially when working with leather, place a brass washer on the other end of the rivet shank. This distributes the pressure and prevents the joint from tearing out.

- Trim the rivet shank with clippers so that it protrudes about 1 to 2 mm beyond the material (or washer).

- With a small hammer (ideally a ball-peen hammer), begin to carefully peen the end of the shank. Use circular strikes around the perimeter until you form a second, so-called "shop" head.

The Art That Built the World

Riveting is one of the oldest and most fundamental engineering technologies. Long before welding or affordable screws became widespread, riveting was the primary method for joining metal parts. Everything from Roman armour (Lorica Segmentata) and Viking ships to Gothic cathedrals and 19th-century steam boilers and steel bridges was held together by thousands of skilfully set rivets.

Interesting Fact: The Hidden Strength of the Rivet

The strength of a riveted joint depended not only on the rivet itself but primarily on the skill of the craftsman. A properly peened joint (often done hot) created immense tension as it cooled, pulling the joined parts tightly together. It was this preload that gave structures their enormous strength and resilience. Every rivet in your armour is a small reminder of this ancient and crucial skill.

Care and Properties

Brass is an alloy of copper and zinc that is naturally resistant to corrosion. It requires no special maintenance. Over time, it may develop a darker patina in the air, which adds authenticity to your creations. If you prefer a shiny appearance, you can easily polish the rivets at any time with a cloth and brass polish.

Specifications

| Material | Solid Brass |

| Pieces per Set | 25 |

| Head Type | Round Head |

| Shank Diameter | approx. 3.8 mm / 5/32 in |

| Shank Length | approx. 13.35 mm / 0.53 in |

| Head Diameter | approx. 7.15 mm / 0.28 in |

| Overall Length | approx. 16.2 mm / 0.64 in |

| Set Weight (25 pcs) | approx. 50 g / 1.76 oz |

We are here for you!