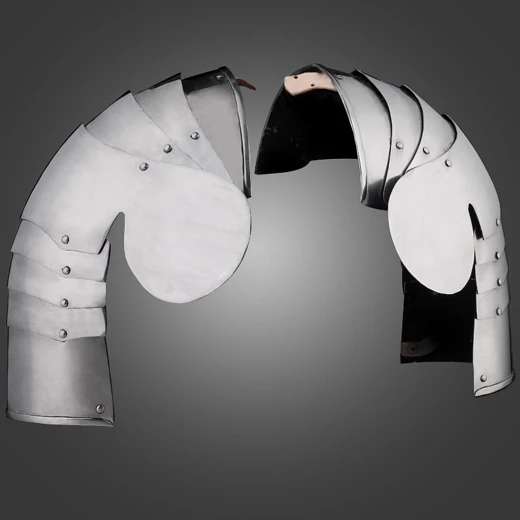

Churburg Pauldrons S18

1xThis original armours are part of the Churburg armoury and is labelled as exhibit "S18". They have a characteristic besagews integrated to the main shoulder segment. This is an unique thing in comparison to other pauldrons from this period, that survived to these days. Although itis oficcially dated 1st ½ of 15th century, some historians maintain it might have benn used in the period 1370-1410. Pieces which this set is based on supposedly belonged to the count Matsch and originated the Lombard´s workshops. More information...

Churburg Pauldrons S18, 1400-1450

Made from 1.6mm thick rusting steel plate. The actual gauge of plate may vary due to the handcrafted way of production.

Approximate dimensions of the pauldrons, see the dimensioned photo:

- a = 21cm

- b = 15,3cm

- c = 39cm

- d = 21,5cm

Made by Marshal Historical

These pauldrons (shoulder plates) are based, as the name suggests, on the armour catalogued as S18 from the Churburg armoury. This armour is discussed as an armour from the early 15th century, sometimes from the late 14th century. Specifically, between the years 1380 and 1410. It belonged to the Earl of Mastch. Earl of March is a title that has been created several times in the Peerage of Scotland and the Peerage of England.

Write to our specialist