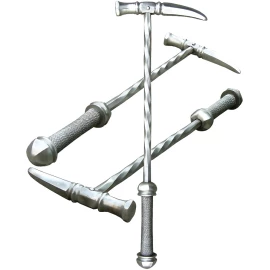

War and battle hammers

A war hammer is a late medieval weapon of war intended for close combat action, the design of which resembles the hammer. The war hammer consists of a handle and a head. The handle may be of different lengths, the longest being roughly equivalent to the halberd, and the shortest about the same as a mace. Long war hammers were pole weapons (polearms) meant for use against riders, whereas short ones were used in closer quarters and from horseback. Later war hammers often had a spike on one side of the head, thus making it a more versatile weapon.

Narrow your Results

War and battle hammers

War hammers

War hammers were developed as a consequence of the ever more prevalent surface-hardened steel surfacing of wrought iron armours of the late medieval battlefields during the fourteenth and fifteenth centuries. The surface of the armour was now as hard as the edge of a blade, so a blade tended to ricochet. Swords, or the blade of a battleaxe, were likely only to give a glancing blow, losing much of the impact, especially on the high curvature of the helmet. The war hammer could deliver the full force to the target.