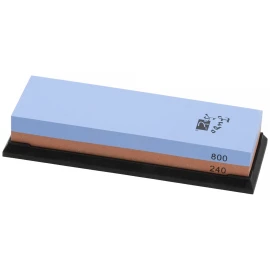

Sharpening stone for knives, grit 1000/3000

1xThis synthetic sharpening stone has an open-pore structure, a homogeneous particle intercalation, and high sharpening performance. It should be used only with water and is suitable not only for Japanese chef's knives. The sharpening stone should be sank in water for 10 to 15 minutes before use. The stone should be wetted regularly during the sharpening process as well. More information...

€33,00

€33,00 excl. VAT

In stock

2

pcs

, dispatch on: 29-Jul-2024

, dispatch on: 29-Jul-2024

Item physically stored in our Warehouse in Kadan

SKU: 82193

Period:

Sharpening stone for knives, grit 1000/3000

Grits up to 1000 are suitable for rougher sharpening; higher grits from 3000 enable fine sharpening of blades.

This is a combined sharpening stone on a non-slip rubber base.

- Grit 1000/3000

- Dimensions 180 x 60mm

- Thickness of the stone: 27mm

Premium quality product, made by Fudo.

24-Jun 2018

Baloun Ladislav

verified review

Bohužel jsem nepochopil strategii vašeho prodeje .19.6.jsem navštívil vaší firmu v Kadani ,chtěl jsem si na místě vybrat brusné kameny ,ale byl jsem odmítnut.Nerozumím tomu. Obrátil jsem se na jinou firmu-

Write to our specialist