Armour parts

Narrow your Results

Armour parts

Armour was an important part of the equipment of every knight. Its purpose was to protect the knights from injuries. Our products are for fans of history, fencers and collectors.

Warriors riding on the horseback were called as the knights in the Middle Ages. Heavy metal outfit of a knight consisted of a (full-suit of) plate armour, a helmet and a shield. Medieval knights were armed with swords, daggers, lances, sometimes also with axes, hammers and maces. Medieval knights were brave, loyal and generous.

You will find many different types of armour for different body parts in this category “Armour parts”. Take a look at leg armour, greaves, sabatons, knee cops. This armour parts protected your legs from cutting and other injury during fighting. Do you attend the medieval battle re-enactments? You will need armour parts definitely!

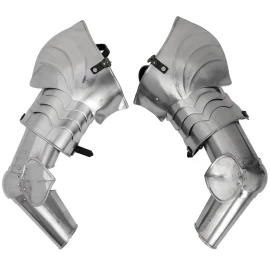

Brave knights had to protect also his hands. Armour parts such as armour arms, iron pauldrons, elbow cops, vambraces and also gauntlets were used for this protection. Knights used finger gauntlets or mitten gauntlets.

Cuirasses, gorgets, suspension discs and belts or jackchains (were sewn on gambesons) were used by knights as other armour parts. You will find also spurs in our e-shop. Chastity belts for ladies and gentlemen are our specialties.

Be ready to fight with our armour parts!