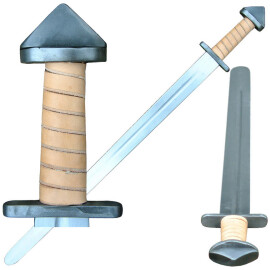

Viking sword Classic, Class A

The oil-quenched spring steel blade is forged up to the end of the hilt and riveted with the pommel. The blade tang is covered with hard wood and wrapped in genuine leather. Cross guard and pommel are made from steel. The blade tip is rounded. More information...

€258,00

€258,00 excl. VAT

Show alternatives

Discontinued and cannot be ordered anymore

Item number: 9666

Period:

Recommended offer

Viking sword Classic, Class A

- Overall length approx. 95cm

- Blade length approx. 76cm

- Blade width at the guard approx. 4.9cm

- Thickness of the blade edge 2.5 - 3mm

- Weight approx. 1250 gr

- Blade made of: EN45 steel

- POB approx. 11-12cm from cross guard

- Blade hardness: 50 HRC

Premium quality by Armourclass, made in the UK

Write to our specialist