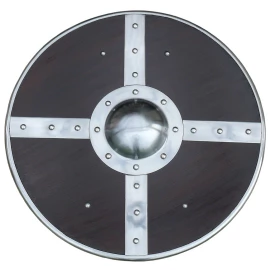

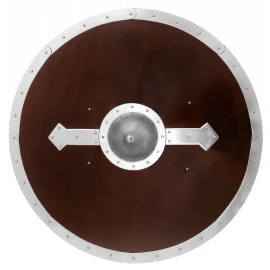

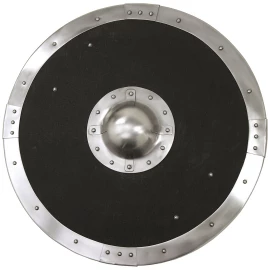

Viking Round Shield Arnlaug 74cm

1xThe wooden base of this Viking Round Shield is made of plywood. It is a layered material of several kinds of wood, usually beech, spruce and birch. The surface layer is always made of the hardest kind. The approx. 12mm thick material consists of about 8 layers. More information...

€231,00

€231,00 excl. VAT

On order,

order now and goods will be dispatched on: 2-Dec-2024

Notify me when the item is in stock.

We will inform you as soon as we stock up.

SKU: mt_801108+madlo

Period:

Viking Round Shield Arnlaug

- Material: wood, steel, felt, cow leather

- Size: Diameter: 74cm

- Gauge of steel plate: 1.5mm

- Weight approx. 5,7 kg

17-Feb 2014

Brandmüller

verified review

Sehr schöne Verarbeitung und liegt gut am Arm auf!

Freue mich auf erste Tests im Schaukampf!

We are here for you

.2204036504.1696357304.jpg.webp)

_01.2723751116.1696357304.jpg.webp)

_02.2723751116.1696357304.jpg.webp)

_03.2723751116.1696357304.jpg.webp)

_04.2723751116.1696357304.jpg.webp)

.2152382459.1696357304.jpg.webp)