Heater shield big

1xThe hater shield dates from 12th to 15th century. It is usually approx. 60cm wide.

After many requests, we offer them in different sizes. Should you wish another size than offered here, note that please the comment of your possible order.

More information...

Heater shield big

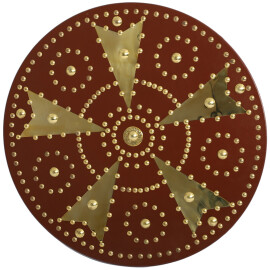

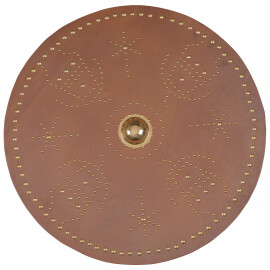

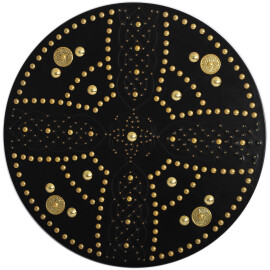

Colored Heater shields helped to distinguish belligerents on the battlefield. The color could be supplemented with a symbol. The front could even be painted with a coat of arms, which was especially designed for ceremonial occasions.

- The heater shield comes with forearm and grip leather straps.

- Made from wood, linen and rawhide

This premium-quality shield is produced in the Czech Republic.

Please find more information to this shield here.

|

Approx. height |

Approx. width |

Approx. weight |

|

90cm |

62cm |

5000 g |

Write to our specialist