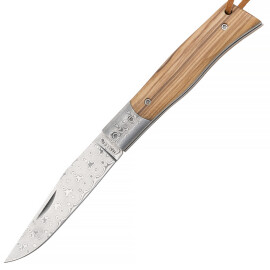

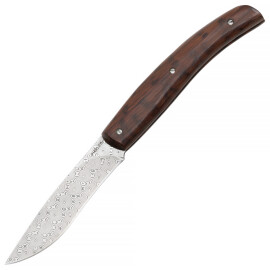

Damascus knives

Damascus knives are knives that have a blade from Damascus steel. Damascus steel is a term derived from the name of the Syrian city Damascus. This steel was imported through this city. Damascus steel is very quality. Specific patterns (patterns of banding and mottling) are characteristic of her. Our e-shop offers various knives with blades from Damascus steel, e.g. pocket knives or knives in a gift box.

Narrow your Results

Damascus knives

This category offers various Damascus knives that have beautiful decorated blades with mottling pattern. Damascus steel is very quality and resilient material. The steel was produced only in India and Sri Lanka once. It was developed in India around the year 300 BC. Products from this steel were imported to Europe much later. Damascus steel is also known as wootz or bulat. It is beautiful material and its pattern looks as flowing water.

The original method of Damascus steel production is not known. Many smiths tried to get to the root of the mysterious production of Damascus steel, but they were not successful. False Damascus (pattern-weld) just was created. It is made by pattern welding. This technology is known as the Damascene. Also Damascus knives are made in this way.

Damascus steel has been used for the production of swords and Damascus knives. Today, however, it is also used for production of jewelleries (mainly thanks to a wonderful pattern on the material). Damascus knives are really quality and beautiful. Take a look at other knives that are offer by our e-shop. You will probably excite about our best knives!