Folding knives

Folding knives, such as the lockback knife or claspknife have locking mechanism such as a twisting ring or catch that must be released in a distinct action before the knife can be folded. This lock improves safety by preventing accidental blade closure while cutting. In contrast, slipjoint knives rely only on a small sliding spring to keep the blade open, and if enough force is applied to the back of the knife, the blade will close.

Narrow your Results

Folding knives

Lockable folging knives have appeared as early as the 15th century. In the late 19th century locking pocket knives were popularized and marketed on a wider scale.

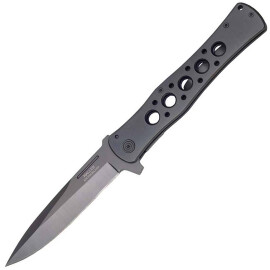

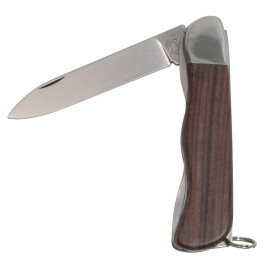

Folding knife

In the 1990s in the United States, as a response to restrictive gun laws, tactical folding knives became popular. In response to the demand for folding knives, production companies offered mass-produced tactical folding knives. There has been criticism against the notion of a "Tactical Folding Knife". Students of knife-fighting point out that any locking mechanism can fail and that a folding knife regardless of lock strength can never be as reliable as a fixed-blade combat knife.