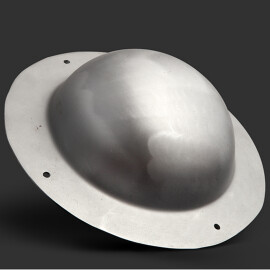

Shield boss Telemark, 10th cen.

This shield boss was made after the original that is on display in the Museum of Cultural History in Oslo (Norway). It comes with holed flange inclusive 4 iron rivets. More information...

€21,00

€21,00 excl. VAT

On order,

order now and goods will be dispatched on 31-May-2024

Item number: 9696

Period:

Iron shield boss with toothed flange Telemark, 10th century

- hand-hammered from carbon steel plate

- 130mm inner diameter

- 157mm outer diameter incl. the flange

- 66mm overall height

- weight approx. 350 g (16 gauge)

Write to our specialist