Survival Knives

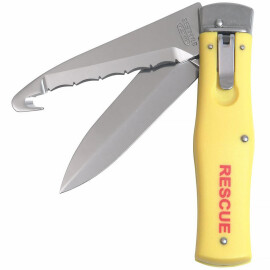

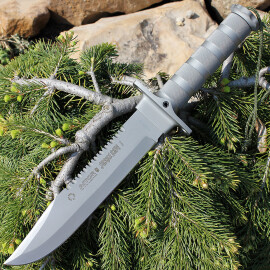

Tactical knives are also described as survival knives are knives intended for survival purposes in a wilderness environment, often in an emergency situation when the user has lost most of his/her main equipment. Military units issue some type of tactical knives to pilots in the event their plane may be shot down. Tactical knives can be used for trapping, skinning, wood cutting and other uses. Hunters, hikers, and outdoor sport enthusiasts use survival knives. Some tactical knives are heavy-bladed and thick; others are lightweight or fold in order to save weight and bulk as part of a larger survival kit. Their functions often include serving as a hunting knife.

Narrow your Results

Tactical knife

Tactical knives are designed for work such as setting traps, cutting branches and skinning animals. Most survival knives have blades that are 4 - 6 inches long with a full thick tang. Survival knives made by Aitor, Lile, Parrish, Randall, or Reeve have hollow handles, which allow the user to store additional equipment in the handle. Some of these knives feature a compass in the cap. On some survival knives, the spine or back of the blade is flat; allowing it to make a good hitting platform when pounding it with a hard stick to aid in splitting wood. See also the section combat knife.