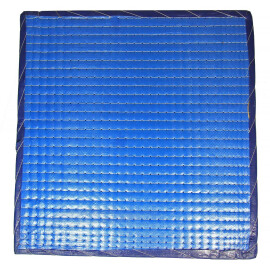

Ethafoam Target 70cm

1xVery light (about 3,3 kg) and durable target, made of Ethafoam Target 70cm (220), coated in the style of a sandwich and equipped with an extremely solid exchangeable center. Exchangeable centers made of ethafoam 400 and ethafoam 700 stop the arrows in an excellent way. Even high-performance arrows, shot with compounds bows, are stopped by this target. More information...

€142,00

€142,00 excl. VAT

Show alternatives

Discontinued and cannot be ordered anymore

Item number: 8466

Period:

Recommended offer

Ethafoam Target 70cm

- Diameter x thickness: 70 x 20mm

- Made in Germany

28-Jul 2017

Lucie Růžičková

verified review

Perfektní terč. Lehounký na přenášení a dost odolný. Zatím mi nic neprošlo skrz, jen okolo, když jsem se netrefila :D Ano, po nějaké době je samá díra, ale na funkčnosti mu to neubírá a pokud díry přece jen vidět nechcete tak si přes to přelepte terč ;)

Write to our specialist

.3485832347.1706976060.JPG)

.3485832347.1710595120.jpg)