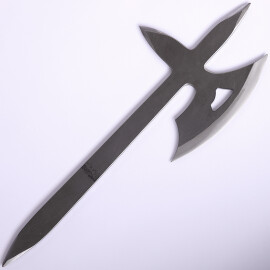

Franconian throwing axe Franziska

The metal parts of the axe are made from the steel according to the technical norm CSN 425308, quality class 1135.1. This is a hot-rolled steel that cannot be hardened. If you wish the smith can use oil-quenched spring steel that is used for sword blades. In that case the price would be higher by 25%. More information...

Franconian throwing axe Franziska

- Shaft length approx. 50cm

- Axe size approx. 19,5 x 11,5cm

- The shaft is made of hard wood, our smith takes according to availability ash, beech or oak.

- Weight approx. 1,10 kg

Guarantee for breaking a throwing axe

A throwing ax is extremely stressed when throwing on the target. Critical is the sudden slowdown, whose character depends in particular on the exerted throwing power, material stiffness and structure of the target. Breaking of a throwing ax cannot be completely ruled out at such use. We experimented with different steels as well as with their heat treatment. We were able to break all throwing axes! The warranty for breakage refers exclusively to steel defects, such as hairline cracks. Throwing axes are always exposed to tear and wear. We will swap (or reimburse) your ax for free if it breaks due to a material defect. In such cases, a material defect is clearly visible on the steel fracture surface. In such cases do not hesitate and send the ax back to our address. A break of the wooden handle is also excluded from the warranty! A replacement wooden stock can be bought in hobby markets such as Hornbach, OBI, Baumax, UNIHobby, etc.

Write to our specialist