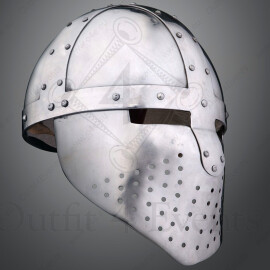

Viking helmet Gjermundbu

€141,00

€141,00 excl. VAT

On order,

order now and goods will be dispatched on 21-Jun-2024

Item number: 5722

Period:

Viking helmet Gjermundbu

Specifications of the Viking helmet:

- Material: 1,3 or 1,5mm / 17 or 18 Gauge Steel

- Weigt approx 2kg (18 gauge)

This helmet can be made to measure after your measurements ‘1a’ to ‘1j’ in this measurement chart.

Please read our instructions, how to determine a helmet size correctly.

Write to our specialist