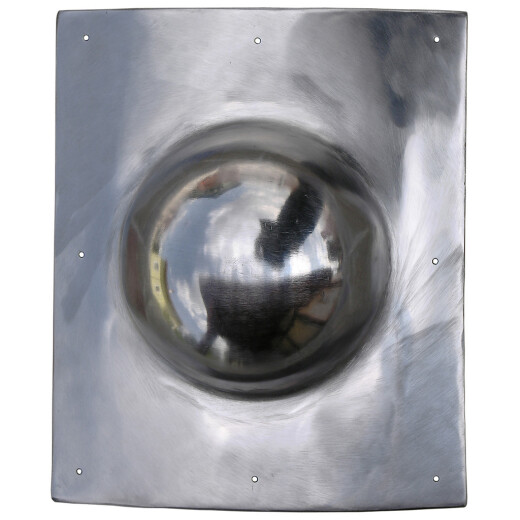

Roman umbo

1x

€38,00

€38,00 excl. VAT

On order,

order now and goods will be dispatched on 31-May-2024

Notify me when the item is in stock.

We will inform you as soon as we stock up.

Item number: 3526

Period:

Roman umbo

Specifications of the Roman umbo:

- Diameter approx. 24 x 20,5cm

- Gauge of plate 16

- Made of carbon stelln (not stainelss)

- Weight approx. 0,85 kg

2-Dec 2016

Michael Koch

verified review

Der Umbo kam heute, nach sehr kurzer Lieferzeit, bei mir an. Die Qualität (und natürlich Stabilität) ist für diesen günstigen Preis mehr als außerordentlich. Außerdem sieht der Schildbuckel sehr wertig aus - die Materialverarbeitung ist wirklich erste Sahne!!!

Write to our specialist

.3485832347.1705833751.jpg)