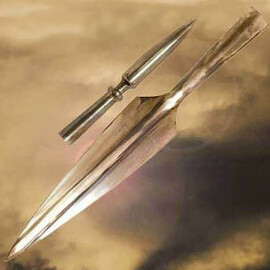

Shaft butt cap, so-called lance foot

Optionally delivery including hardwood pole of approx. 40mm diameter. There are pre-drilled holes from two sides. Two nails for attachment on a shaft included. More information...

€9,70

€9,70 excl. VAT

In stock

22

pcs

, dispatch on 26-Apr-2024

, dispatch on 26-Apr-2024

Item physically stored in our Warehouse in Kadan

These variants are in stock

Size:

M

4

pcs

4

pcs

Size:

L

18

pcs

18

pcs

Shaft butt cap, so-called lance foot

The shaft butt cap is available in 2 sizes:

Size M

- Length 95mm Ca

- Diameter above 35mm Ca

- sharp tip as per photo

- made from 1.5mm / 16 gauge carbon steel plate (not stainless)

- Weight approx. 52 g

Size L

- Overall length approx. 200mm

- Diameter above approx. 50mm

- rounded lower end Ø approx.20mm

- made from 2mm / 14 gauge carbon steel plate (not stainless)

- Weight approx. 332 g

The specified dimensions and shape may vary slightly from piece to piece.

Write to our specialist