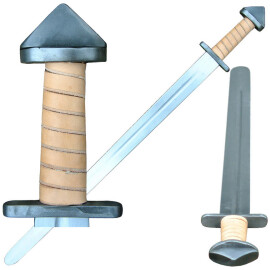

Viking spatha sword Øyen

1xHistorical classification of the sword style: Type F after the Dr. Jan Petersen's Typology More information...

€277,00

€277,00 excl. VAT

On order,

order now and goods will be dispatched on 8-Jul-2024

Item number: 1121

Period:

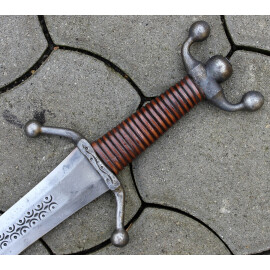

Viking spatha sword de luxe Øyen

Specifications of the Viking spatha sword de luxe Øyen

- Overall length approx. 90cm

- Blade length approx. 70,5cm

- Guard approx. 11,5cm

- Weight approx. 1,30 kg

- battle ready (blunted version)

- Blade of spring steel W.Nr. 1.7102 (DIN 54SiCr6) quenched to a hardness of approx. 53 HRC

Made in the Czech Republic.

Please read our: Directions for the use of bladed weapons.

14-Nov 2022

Herbert Heinrich RAICH

verified review

Ich habe bereits einige Schwerter besessen, aber eine dersrt perfekte Arbeit hatte ich noch nie in meiner Sammlung gehabt. Gratulation an den Schmied aus Tschechien Herrn Rudolf Krutský.

Sicher nicht mein letztes Schwert, dass ich von diesem Schmied anfertigen lasse

Write to our specialist