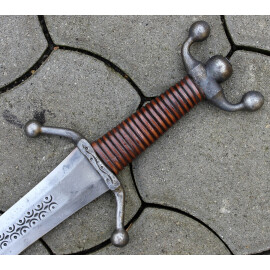

One-and-a-half sword Haunild

€168,00

€168,00 excl. VAT

On order,

order now and goods will be dispatched on 6-Jun-2024

Item number: 1032

Period:

One-and-a-half sword Haunild

Specifications of the one-and-a-half sword Haunild:

- Overall length approx. 123cm

- Blade length approx. 92cm

- Guard length approx. 24,5cm

- Weight approx. 2,70 kg

- Blade of spring steel W.Nr. 1.7102 (DIN 54SiCr6) quenched to a hardness of approx. 47 HRC

Made in the Czech Republic.

Please read our: Directions for the use of bladed weapons.

Write to our specialist

.3485832347.1707678837.JPG)